Our research group has a range of unique capabilities, including those for materials synthesis and processing; materials characterization; and materials analysis. We also have more general equipment and access to sophisticated instrumentation through Iowa State University and Ames Laboratory.

Key Equipment / Techniques / Capabilities

Characterization Capabilities

Tensile Test Load Frame

Nanoindentation

Powder Processing (Hall Funnel)

Metallographic Specimen Prep.

Defect Characterization

Description

Specifications

Description

The Micro Materials NanoTest nanoindentation system allows for fine scaled mechanicalpropertymeasurement. It uses sharp diamond tip with a known geometry to indent into small regions of samples. TheNanoTest measures the force that is exerted on the sample and the depth that the indenter goes into the sample. Because the geometry of the indenter tip is known, the contact area can be calculated. With these pieces of information, hardness, Young’s modulus, and other mechanical properties can be measured for small sample regions. Our nanoindenter can also collect measurements at elevated temperatures and in a controlled atmosphere.

Specifications

Load:5–500mN

Thermal drift correction

Temperature range: 20C–800C

Atmosphere: Air or argon

Description

We maintain powder handling and measurement capabilities, including an inert atmosphere glove box, scales, Hall flow meter, RoTap sieve shaker in sound isolation box.

Its "Scientific Story" in our group

Our group often works with powdered materials, and we maintain the safety protocols and equipment to handle powder safely.

Description

The heart of our characterization begins with an exceptional metallographic specimen preparation capability. We have a range of polishing capabilities ranging from manual to fully automatic polishers with independent load control to parallel polishers for the finest detailed work. We also have a vibratory polisher for the last steps, and various saws for sectioning material.

Details of Instruments

TechCut 4™ Precision Low Speed Saw

The TechCut 4™ is a precision low speed saw used for the sectioning of small and delicate samples. The saw is most used to section material from tensile samples for subsequent microstructure characterization.

Specifications:

Variable speed with LED display: 10-500 RPM (10 RPM increments)

Micrometer sample indexing: 0-25 mm range (0.002 mm resolution)

Variable sample loading: 0-300 grams

Cutting capacity: 2” (51 mm) thickness

TechPress 3™ Mounting Press

The TechPress 3™ is used to mount material for metallographic sample preparation. The operator can choose to input a program manually or choose a program from a database of 80 preloaded, adjustable parameters for mold size, single mount or duplexing, mounting resin, curing time and temperature, cooling time, and pressure.

Specifications:

Selectable units: psi/BAR and °C/°F

Molding pressure: up to 4500 psi (310 Bar)

Heat power: 1500 W

Curing temperature: 0-200°C (32-392°F)

Curing time: 0-100 minutes

Cooling time: 0-100 minutes

MultiPrep™ Polishing System – 8”

The MultiPrep™ is a semiautomatic system that allows for precise sample preparation using the front (sample advancement) digital indicator to display real-time material removal and the rear (static) digital indicator to display absolute vertical position. Dual micrometers (pitch and roll) can be used to control the angular positioning head to allow for parallel polishing, angle polishing, site-specific polishing, or any combination thereof.

Specifications:

Digital indicator resolution: 1 μm (sample advancement and static)

Dual axis micrometer: +10° / -2.5° range (0.02° increments)

Variable sample load: 0-600 g (100 g increments)

Variable platen speed: 5-350 RPM (5 RPM increments)

Automatic sample rotation: 8 speeds (full or limited)

M-Prep 5 ™ Grinder/Polisher (2)

The M-Prep 5™ is a grinding/polishing system that is used for manual metallographic sample preparation. The magnetic platens and PTFE support discs allow for greater versatility of grinding and polishing operations for a single system.

Specifications:

Variable speed with digital display: 10-500 RPM (10 RPM increments)

Platen diameter: 8” or 10”

MetPrep 4™ PH-6™ Grinder/Polisher with Power Head

The MetPrep 4™ is a semiautomatic sample preparation system that allows for up to 25 programmable steps for maximum versatility. The PH-6™ power head can prepare up to 6 samples simultaneously when operated in individual force (IF) mode and up to 12 samples simultaneously when operated in central force (CF) mode.

Specifications:

The following setting can be individually adjusted in each of the 25 steps:

Platen RPM: 50-400 (10 RPM increments)

Mode: Complimentary/Contradictory

Time: 0-120 minutes (15 second increments)

Sample RPM: 0-150 (10 RPM increments)

Force: Individual/Central (adjusts force value accordingly)

Force: LbF (pound-force) or N (Newton), selectable units

Central: 5-90 LbF (1 LbF increments) or 22-394 N (~4 N increments)

Individual: 0-22 LbF (1 LbF increments) or 0-96 N (~4 N increments)

Fluid: Off, Water, AD-5™ (fluid dispenser)

Rinse: 0-60 seconds (1 second increments)

Friction Reduce: On/Off

Reduce Time: 0-60 seconds (1 second increments)

Reduce %: 0-90 (10% increments)

Friction Start: On/Off

Description

Our group continues to develop new methods related to these general capabilities. For example, in defect characterization, we are looking into new NDE ways to measure porosity <0.5% or to determine their proximity to a free surface with near micrometer resolution. Similarly, we are working on new techniques to calculate dislocation densities by revisiting classical 4-point probe techniques.

Analytical & Computational Tools

Machine Learning

FEA-based analytical tools

Optic Studio

Description

Our efforts seek to couple fundamental physics with advanced machine learning / artificial intelligence approaches.

So, with apologies to the Bard, this reflects our efforts and theories:

Two methods, both alike in dignity,

In fair sciences, where we lay our scene.

From ancient elegance break to methods mutinous,

Where machine learning makes physical laws unclean,

From forth the noble loins of these two foes

A pair of cross-term’d numbers seek their place;

Whose serial expansions, equally covariant

Do with their projections, bury their parents strife.

Our fearful assessment of their dual-space truth,

And the continuance of their parents, sage,

Which, for their children’s union, sought to achieve,

Is now the two hours’ traffic of our stage;

The which, if you with patent eyes attend,

What here shall miss, our toil shall strive to mend.

Specifications

Developed within the group and in collaboration with other groups.

Its "Scientific Story" in our group

The seminal work of D.J.C. MacKay, who incorporated Bayesian statistics and developed practical backpropagation modeling, served as the precursors to this approach and our efforts. H.K.D.H. Bhadeshia built upon and worked directly with MacKay to study complex problems involving metallic materials. R.J. Grylls then began conducting limited investigations of the effects of single input variables on an output, publishing after he joined H.L. Fraser’s research group. Fraser et al., also aided initially by MacKay, Grylls, and Bhadeshia, began to conduct research into applying artificial neural networks for complex physical processes in metallic materials, defining these assessments of a single variable on an output as “virtual experiments,” which permitted a well-trained neural network to be probed to determine the influence of one variable on a physical property while all of the other potential independent variables were artificially held at their average values. During this time, Fraser and Collins understood that these virtual experiments were slices through an n-dimensional hyperspace, and it became obvious that the lower dimensional slices could be described using simpler functions than the full neural network, a domain-specific recognition of the manifold hypothesis. Following this prior work, with the assumption that a mapping was possible between the basis vectors of the n-variable hyperspace equally represented by the expansion of terms of an artificial neural network and the basis vectors representing the physical processes, Ghamarian and Collins sought to establish a constitutive equation for the room temperature yield strength of a titanium alloy given variations in its compositional and microstructural states. They applied a hybrid artificial neural network-genetic algorithm method that optimized the unknowns in a postulated physically-based equation, testing the optimized physically-based model against slices through a hyperspace function representing the neural network model and the data. This latter effort was quite inefficient, but resulted in a physically-based equation that was demonstrated, in subsequent work, to be generalizable to multiple processing and compositional variations.

Description

Finite–Element Modelling (FEM) or Finite–Element Analysis (FEA) is a powerful tool that discretizes a continuous domain into voxels. This allows for powerful analysis of various geometries, assemblies and processes that may or may not have a ‘classical’ solution available. For those applications that have classical solutions, FEM/FEA allows for inspection of details in the continuum that may have not been obvious when using a first–order/classical approach, or for optimization purposes that would be overly time–consuming otherwise.

Specifications

Abaqus

Finite–Element Modelling (FEM) software package initially developed in 1978 by D’ASSAULT Systèmes. Often considered the ‘gold–standard’ of FEM packages and known for its highly customizable andgeneral–purpose nature. Capable of explicit, implicit and frequency based solutions.

COMSOL Multiphysics

Finite–Element Modeling (FEM) software package developed in 1986. Known for the ability to solve weak–form differential equations and unit–aware architecture. Extensible through Java and MATLAB APIs. Also highly customizable through APIs and various physics modules that are available (electromagnetics, structural mechanics, acoustics, fluid flow, heat transfer, and chemical engineering).

Its "Scientific Story" in our group

We have used FEA-based modeling and simulation for multiple problems, including: time-dependent thermal histories of additive manufacturing, ultrasonic fatigue testing of small beams, and Eddy current analysis of signals of near-surface porosity.

Description

Specifications

Its "Scientific Story" in our group

Manufacturing Capabilities

Casting/Foundry

Fused Deposition Modeling (FDM)

Resin 3D Printing

Heat Treatment Furnaces

Soldering Workstation

Powder Mixing Equipment

Description

We maintain a basic foundry primarily for teaching purposes in the department. The furnace is a modern tip/pour electric furnace capable of melting many metals, though we primarily cast aluminum.

Specifications

Electric furnace

Sand casting capabilities and ancillary equipment

Investment castinc capabilities

Its "Scientific Story" in our group

The foundary was in a state of disuse when we came in. As part of a safety upgrade to the facilities, we replaced an older gas furnace with the modern electric furnace. The work space is “hot work” certified, and has a welding station, sand boxes, a muller, and various molds. We regularly conduct aluminum wedge castings to teach the effect of solidification rates on the resulting microstructure, dendrite size, and porosity size/fraction.

Description

Specification

Story

Description

Specification

Story

Description

The group maintains heat treatment capabilities. In addition to the Gleeble thermalmechanical simulator, we have two high temperature box furnaces and one custom made vertical drop furnace.

Specifications

Ney Vulcan 3-1750 Box Furnace with Programmable Controls (2)

The Vulcan box furnaces can be used to conduct traditional heat treatments with user defined heating and cooling rates and temperature set points. A programmable controller with 9 three-stage programs (6 segments each) and one program with a single temperature hold allows for a wide range of heat treatment applications.

Specifications:

Temperature range: 50-1100°C (1°C resolution)

Temperature accuracy: +/-5°C at steady state

Temperature rates: 0-40°C/minute (positive and negative, 0.1°C resolution)

Hold time range: 0:00-99:59 (hours:minutes, 1 minute resolution)

Internal dimensions: 12.5” x 14” x 10” (D x W x H)

Custom Atmosphere controlled vertical drop furnace

Atmosphere controlled, programmable, with a externally trigger to drop the sample, plunging it into a quench capability.

Description

Specifications

Its "Scientific Story" in our group

Description

Specifications

Its "Scientific Story" in our group

Key Equipment: Additional Information

The Gleeble

Description

The Gleeble 3800 thermomechanical physical simulator is capable of the simultaneous control of both temperature and load cycles. This permits us to precisely control thermal and mechanical loading to simulate a wide range of processes. We have the possibility of expanding its capabilities through other mobile conversion units, potentially permitting us to simulate torsion and ECAP-like processes.

Specifications

Maximum Stroke: 100 mm

Maximum Stroke Rate:2,000 mm/sec

Minimum Stroke Rate: 0.001 mm/sec

Maximum Force (compressive): 20 tons (metric)

Maximum Force (tensile): 10 tons (metric)

Maximum specimen size: 20mm diameter

Maximum Temperature: 3,000°C

Maximum Heating Rate: 10,000 °C/sec

Maximum Quenching Rate: 10,000 °C/sec

Its "Scientific Story" in our group

The Gleeble was with our research group at Iowa State almost from day one. It was one of a few capabilities that we knew would form the foundation of our group. We knew of its capabilities to permit the very precise control of thermal (and thermomechanical) history under controlled environments, which would be enabling for our extensive work with titanium alloys. This capability would be essential for us to conduct relatively rapid processing to set a range of microstructures that could then be tested, permitting us to explore the composition-microstructure-property space. However, soon after arriving, we were able to conduct another type of test: thermal gradients and so-called bi-combinatorial studies, where composition could be varied along one axis and a thermal gradient along an orthogonal axis. In this manner, we are able to shrink the number of tests required for developing time-temperature-transformation plots.

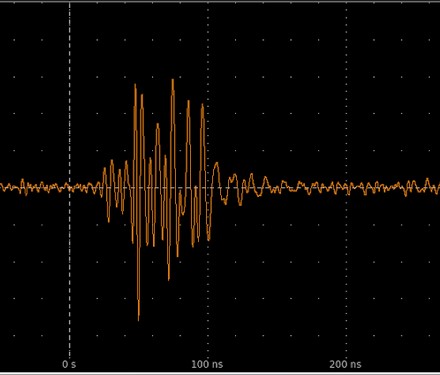

SRAS

Description

Spatially Resolved Acoustic Spectroscopy (SRAS) is a laser ultrasound technique that can infer crystallographic orientation information from materials. Previously, this data was only obtainable through X–Ray Diffraction analysis for powders and Electron Backscatter Diffraction analysis for small bulk samples. SRAS can provide similar information at a lower resolution, while operating on the meter–scale.

SRAS has existed in some form for over twenty years, developed by Drs. Steve Sharples and Matt Clark of the University of Nottingham. It however, hasn’t been grafted on to a serial sectioning system (Robo–met.3D™) to provide 3–dimesional, voxel–based reconstructions of crystallographic information until now. Our group has worked on developing and deploying this custom capability.

SRAS provides EBSD-like orientation data at a much coarser resolution and larger length scale. Free from expensive and constraining electron microscope systems, SRAS allows us to investigate crystal structure at length scales that would be difficult to analyze, or just generally unobtainable due to size. As texture at the mm to 10’s of mm scale is present in larger scale AM processes, such as Electron-Beam Additive Manufacture (EBAM), this is a critical quantification needin order to fully study the process.

Specifications

We are building two systems.

SRAS integrated into the Robo-Met.3D™:

- Supply: 110V/2ph

- Bespoke inverted imaging system

- THORLabs MLS203–1 High Speed Scanning Stage (110x75mm)

- ZABER LSQ Slides (600mm/300mm) for sample shuttle

- Typical Z–Resolution: Set by Robo–met.3D™

- Typical XY Resolution: 100um/px (scan direction) x 0.1, 0.25, 0.5 mm/px (step direction)

- Coherent Genesis MX (532nm TEM00) and Helios(1064nm <1ns Q–Switch) Lasers

- High speed physical knife–edge detector (<500MHz)

Gantry-style SRAS system:

Under development

Its "Scientific Story" in our group

In 2016, while at an AFRL/FAA working group meeting on cold dwell fatigue, and wrestling with needing th analyze the orientation of grains over very large areas for another program on large-volume additive manufacturing, I wondered whether it would be possible to be possible to use Surface Acoustic Waves to back out crystal orientation spatially. After a moment or two of looking, I realized the team at the University of Nottingham had already achieved this, and, fortituously, folks familiar with the team were sitting next to me, and others in the room were aware of potential technical challenges of this emergent technique. A few hours and emails later, and we were on our way to writting our first proposal to bring the technique to the Western Hemisphere.

We are delighted to have found scientific friends through our interactions and collaborations with the team at the University of Nottingham.

The mLab Cusing

Description

MLABCusing is a metal 3D printer capable of manufacturing small parts with delicate structures.A 3D object file can be loaded intoMaterialiseMagics software in order togenerate a sliced view.TheMLAB uses a laser to precisely melt metal powderin a controlled atmosphere at the geometrydefinedlocationsfromthese slices and then apply a new layer of powderontop before repeating this process.Samples can bethenremoved from the build plate.The automatic sieving station allows for re–useof thepowder to reduce waste. We have the option of building using reactive metals like titanium as well.

Specifications

Laser: 100W continuous wave

Build volume: 90mm x 90mm x 80mm (x,y,z)

Build atmosphere: Argon

Powder: Stainless Steel 316L, others possible

Slicing software:MaterialiseMagics

Its "Scientific Story" in our group

We have a long history of researching additive manufacturing, including the original directed energy deposition powder blown methods and large-scale wire fed systems. The Concept Laser was donated by GE and has enabled us to begin working more actively in the SLM space. It also provides an educational opportunity for a variety of students in our department and beyond.

Powder blown DED system (beamline)

Description

This instrument was developed and built in the group and in partnership with Ames Laboratory. The objective was to build the first powder blown directed energy deposition system designed to be operated in a beam line environment and thus uncover the relevant physics associated with powder blown systems, including powder/molten pool interaction, convection, and liquid/solid and liquid/atmosphere interactions.

Specifications

Laser: 500W continuous wave IPG laser

Build volume: 100mm x 100mm x 100mm (x,y,z)

Axes: 6 axes

Build atmosphere: Argon

Powder: All (demonstrated on Ti)

High precision stages for independent motion and imaging/diffraction experiments.

Its "Scientific Story" in our group

We have a long history of researching additive manufacturing, including the original directed energy deposition powder blown methods and large-scale wire fed systems. This system will be used in upcoming research programs designed for beam line analysis and the development of new sensors.

Robo-Met.3D

Description

The RoboMet.3D allows forfully–automatedpolishing and optical imaging of samples, including serial sectioning. It consists of a polishing wheel with automatic platen changer and solution dispenser. The system also has a robotic arm that grabs and transfers the sample between the polishing wheel, sample cleaning section and Zeiss optical microscope. The Zeiss microscope has motorized sample stage to allow for wide area mosaic view for features of interest. These systems come together to allow for automatic 3Dmicrostructuralimaging.

Specifications

Automated polishing systemoMulti–platen cassette system for polisheroAutomatic polishing solution dispenser for 6 solutions + water

Fully automated inverted microscope

Cleaning stationo2 ultrasonic cleaning stationso3 washing/etching/dip well stationso1 drying station

Slice Thickness: 0.2 –10 micronsSlice Rate: Up to 20 per hour

Sample Size: 1.25″ or 1.5″ mounted samples, additional flat plate holder for other geometries

Etching: Automatic

Optical Illumination: Bright Field

Microstructural Data Collection: Real time

Its "Scientific Story" in our group

The Robo-Met.3D is another system with which our group has extensive experience. We value its ability to make 3D materials characterization more accessible. In this system, which was funded under an ONR DURIP program and installed in 2018, we have worked to integrate SRAS into it as another characterization instrument.

Precession Electron Diffraction (PED)

Description

Precession Electron Diffraction is a technique that decreases the dynamical behavior of electron diffraction by tilting and precessing the electron beam (TEM) along a conical surface with the apex in the sample plane. PED reduces kinematically forbidden reflections and multiple scattering. These factors come together to improve TEM diffraction images.

DigiSTAR interface controls the coils in a TEM to achieve the correct compensation for any spot size to achieve stationary electron diffraction patterns during the diffraction. These patterns change from conventional dynamical diffraction (0 mrad precession angle) to quasi–kinematical (50 mrad or more, TEM dependent).

PED data can be used for identifying weak X–Ray reflections, estimating accurate individual hkl intensity contributions in case of overlapping X–Ray intensities, and obtaining crystallographic phases of hkl reflections.

Using TOPSPIN software, area scans of diffraction images can be collected. These images can then be indexed to provide phase and crystallographic orientation information down to 1nm resolution.

Specifications

TEM: FEI Tecnai G2–F20 at the Sensitive Instrument Facility.

Automatic precession alignment with TOPSPIN control software.

Automatic diffraction pattern indexing with ASTAR.

Reciprocal lattice reconstruction (3D) capabilities.

Its "Scientific Story" in our group

We began our work with precession electron diffraction before it was widely known, purchasing our first system in early 2011. When the group transitioned to Iowa State University, it was part of the first infrastructure we reestablished. We have used it to develop new ways of quantifying and spatially mapping dislocation densities, assess the character of large populations of grain boundaries, and are, to this day, imagining new ways to use it to extract critical information regarding the crystal structure, interfacial structures, and defect structures of materials, as well as assess symmetry.