Location: 3355 Hoover Hall

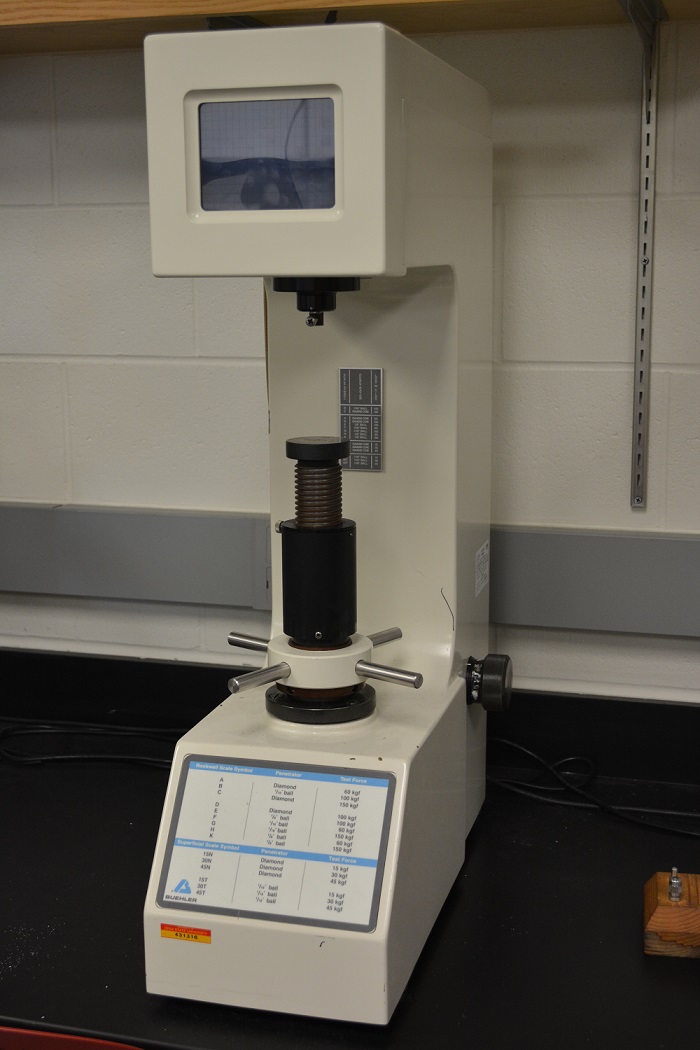

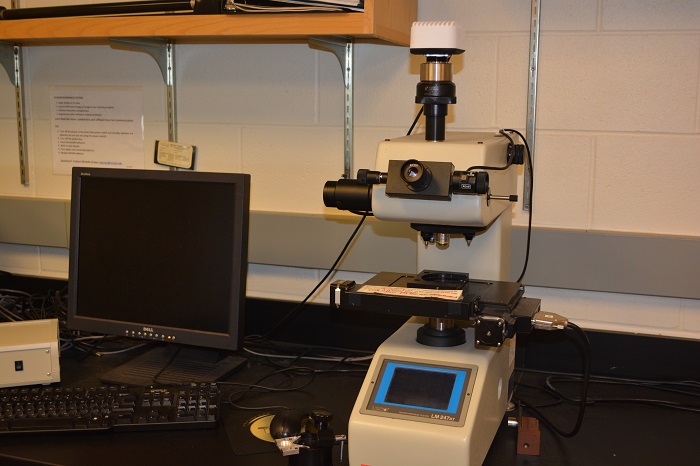

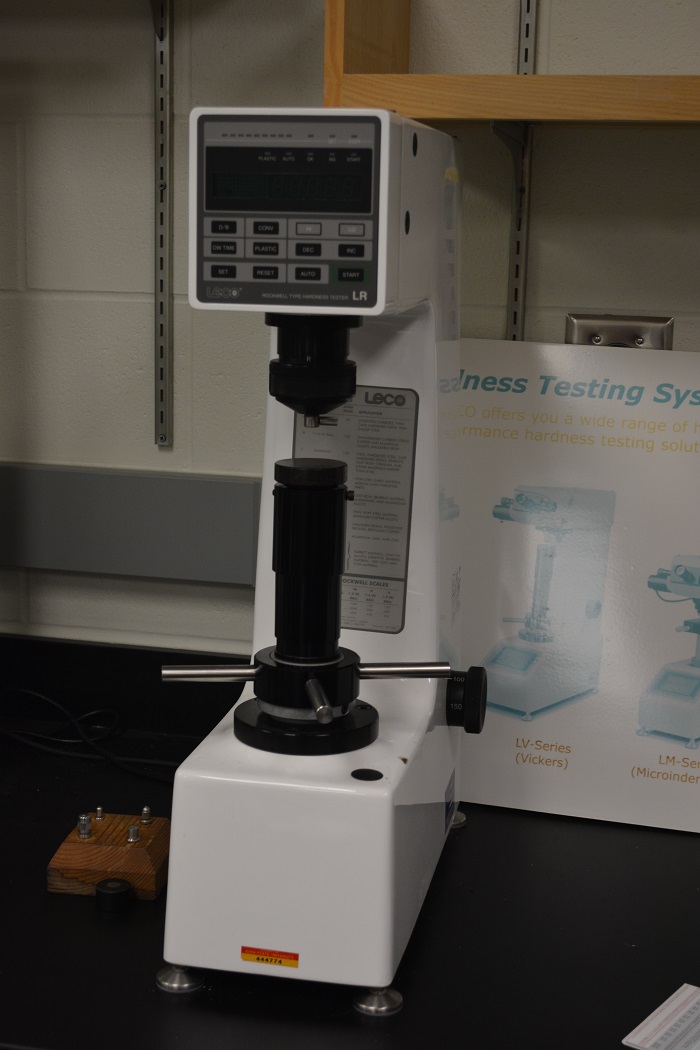

The Metallography Lab has a variety of optical microscopes and hardness testing devices available for use by undergraduate classes or graduate researchers. After preparing samples in the Polishing Lab, students and researchers can examine the microstructure of the samples using the optical microscopes or stereomicroscopes. Both sets of microscopes are equipped with digital cameras. In addition, micro-hardness and macro-hardness testing of samples can be performed in this lab.

For equipment questions, lab concerns, safety problems, or general help in this room, contact mselabs@iastate.edu.